Measuring moisture in oil is important for several reasons:

-

Equipment Performance: Moisture in oil can have a detrimental effect on the performance and reliability of machinery and equipment. Excessive moisture can cause corrosion, wear, and degradation of lubricants, leading to reduced equipment lifespan, increased maintenance costs, and potential breakdowns. By measuring moisture levels, operators can identify and address issues before they cause significant damage.

-

Contamination Control: Moisture in oil can act as a catalyst for other types of contamination, such as oxidation, sludge formation, and microbial growth. These contaminants can further degrade the oil and impair its lubricating properties. Regular moisture measurement allows for proper maintenance and the implementation of effective contamination control strategies.

-

Oil Quality Monitoring: Moisture content is a critical parameter in assessing the overall quality and condition of oil. Monitoring moisture levels helps ensure that oil meets the required specifications and remains within acceptable limits. It allows operators to determine if the oil needs to be changed or if additional purification steps, such as dehydration or filtration, are necessary.

-

Process Optimization: In various industrial processes, such as power generation, manufacturing, and oil refining, moisture content in oil can impact process efficiency and product quality. By measuring and controlling moisture levels, operators can optimize process parameters, reduce energy consumption, minimize product defects, and enhance overall productivity.

-

Safety Considerations: Excessive moisture in certain types of oil, such as insulating oil in electrical transformers, can pose a safety risk. Moisture can lead to insulation breakdown, resulting in electrical faults, fires, or explosions. Regular moisture measurement helps ensure the safety and reliability of such systems.

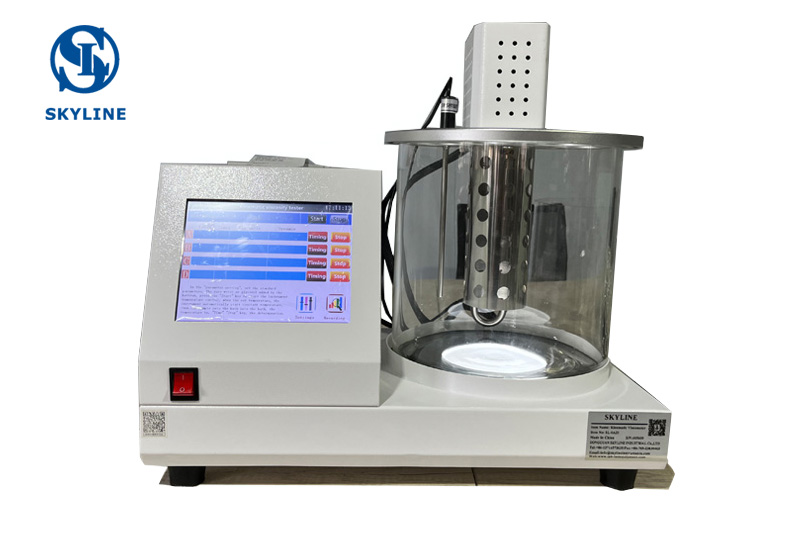

To measure moisture in oil, different techniques are employed, including Karl Fischer titration, capacitance-based sensors, and spectroscopic methods. These methods allow for accurate and timely assessment of moisture levels, facilitating proactive maintenance and enhancing the performance and longevity of equipment and processes.